Belts & Hoses

Exposure to heat, vibration and contamination makes belts and hoses wear out faster than any other components in your vehicle.. That’s why regular inspections are so important. Here are the belt and hose types in your vehicle, along with their applications.

- Alternator

- Water Pump for engine cooling

- Power Steering Pump

- Air Conditioning Compressor

- Radiator Cooling Fan

- Many late model vehicles use a single serpentine belt in place of individual belts to drive these accessories.

- Radiator and Heater Hoses – These hoses convey coolant to the engine and heater core.

- Fuel Hose – As the name implies, this hose transports gasoline from the tank to the engine.

- Power Steering Hose – It connects the power steering pump to the steering gear.

Brake Systems

Brakes are one of the most important safety features that your vehicle offers. Brakes should be inspected frequently to ensure the safety of both you and your passengers. Squeaking is not the only sign that your brakes may need replacement. Grinding, vibration when braking, a squishy feel when you push your brake pedal down, or your vehicle pulling to one direction when braking. Frequent requests for brake inspections to look for issues with uneven pad wear or rotors that need turning quicker than pad replacement is needed is a good way to make sure that your vehicle has the optimum ability to brake when you need it most. If you are experiencing any of these symptoms, please bring your vehicle in as soon as possible so we can inspect and recommend any repairs or replacements that may be needed.

The brake system is actually composed of two kinds of systems—Hydraulics and Friction Materials.

- Master Cylinder

- Brake Lines and Hoses

- Wheel Cylinders and Calipers

- Disc Brake Pads and Drum Brake Shoes

Types

- Disc Brakes

- Drum Brakes

- Parking Brake

- Anti-Lock Brakes: A System Built For Safety

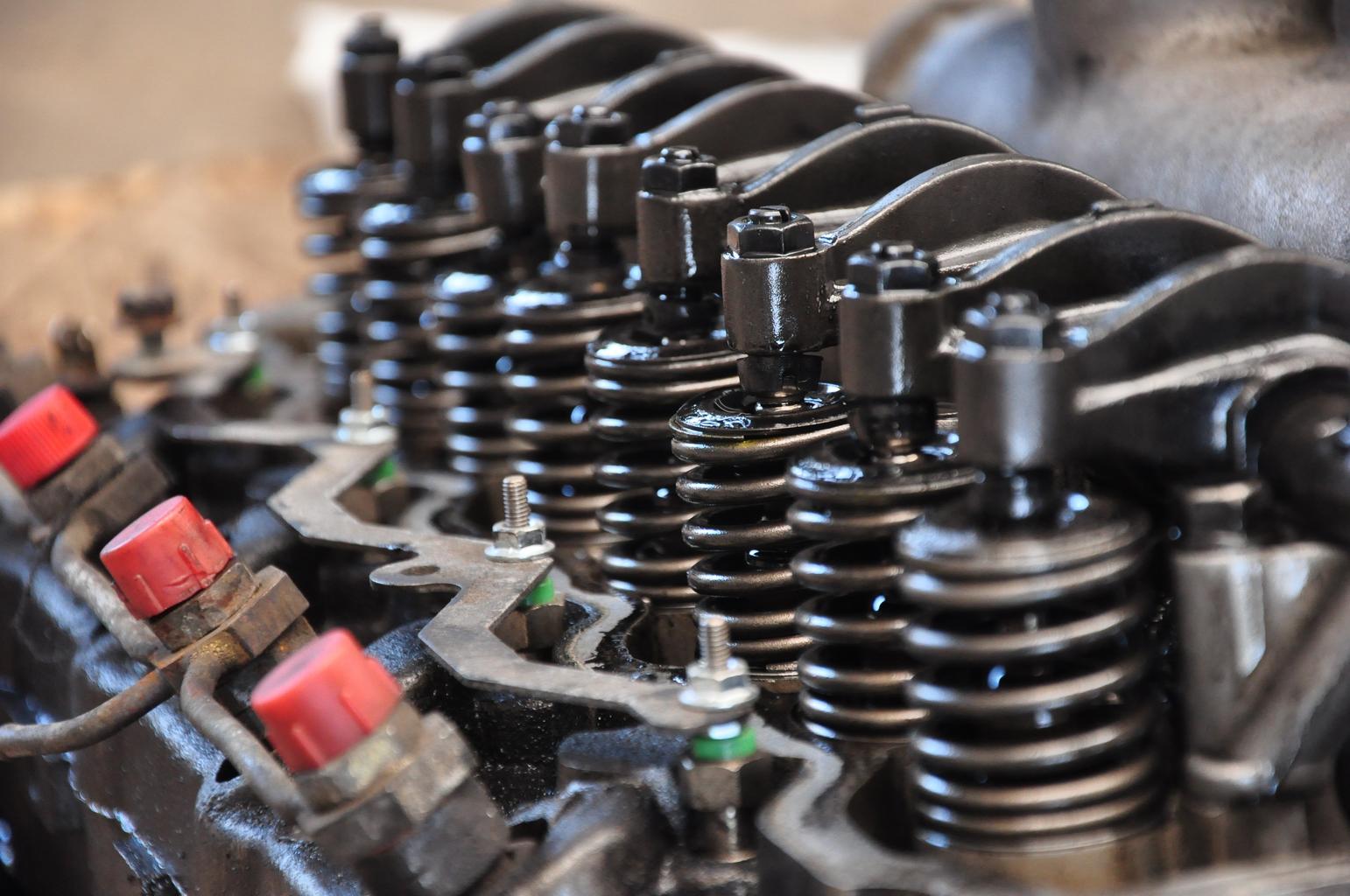

Computerized Engine Analysis

Your vehicle’s engine is a highly sophisticated piece of equipment. Federal Exhaust Emission and Fuel Economy regulations demand that today’s vehicles be equipped with electronic engine control systems, to curb carbon emissions and increase fuel efficiency. With technically-advanced control systems taking the place of simple engine components, common maintenance services such as tune-ups are also a thing of the past. Regular services (such as spark plug and filter replacements) are still required, as well as a computerized analysis of your vehicle’s control computer. Our trained technicians are here to provide these basic services.

A network of sensors and switches convert and monitor engine operating conditions into electrical signals. The computer receives this information, and, based on information and instructions coded within this computer program, commands are sent to three different systems: ignition, fuel, and emission control. Whenever a problem arises (as seen by that nagging “check engine” light), our techs check whatever command is prompted, in addition to the status of your engine control computer and sensors. That way you’ll know if your vehicle’s performance is caused by a real problem, or just a sensor/computer issue.

Vehicle sensory components:

- Mass airflow sensor

- Throttle position sensor

- Manifold absolute pressure sensor

- Coolant temperature sensor

- Exhaust oxygen sensor

- Crankshaft position sensor

- Camshaft position sensor

Cooling System Maintenance

Heating and Air Conditioning Systems

Visual Inspection

- Interior controls and blower

- Radiator coolant level, hoses, pressure cap and thermostat

- The A/C compressor belt for condition and tension

- Leaks or other damage

- Component condition, leaks or damage

Heating and Air Conditioning Tests

- Pressure test engine cooling system

- A/C system pressures are measured and compared to manufacturer’s specifications

- A/C system is leak tested

- Both the heater and A/C are performance tested by checking the outlet air temperature at the discharge vents

Oil changes

Follow your vehicle manufacturer’s recommendation, for oil changes based on your individual driving habits and conditions, and have the oil changed accordingly. Typically this can range anywhere from 3000 – 7,500 miles. We will perform an oil and filter change service which includes a new filter, 5 quarts of new oil, using the oil type recommended for your vehicle, including synthetic blend, high-mileage, or full-synthetic oil. We will top off your fluids and we will check other filters, including the air filter, cabin filter, and fuel filter. We also check your vehicle’s engine belts, hoses, and windshield wipers. As well as topping off all vehicle fluids.

Suspension and Steering Systems

The primary function of your vehicle’s suspension and steering systems is to allow the wheels to move independently of the vehicle, while keeping it “suspended” and stable. Any play or uncontrolled motion in these systems results in a deterioration of handling and accelerated tire wear. Vehicle alignment is closely tied to the condition of the suspension and steering systems.

Steering Systems

Worn or loose components affect the ability to control the toe angle, and may result in a loss of directional stability and accelerated tire wear. The main components of a Conventional system are:

- Steering Gear Box

- Center Link

- Pitman Arm

- Idler Arm

- Tie Rods

The main components of a Rack and Pinion steering system are:

- Rack and Pinion Assembly

- Bellows Boots

- Tie Rods

Suspension

Worn or loose components affect the suspension systems ability to control motion and alignment angles, resulting in a deterioration of vehicle handling and stability, and accelerated tire wear. The main components of the suspension system are:

- Control Arms

- Ball Joints

- Springs (Coil or Leaf)

- Shock Absorbers

- Struts